Airtightness is the most important and difficult challenge in achieving California’s 2020 energy-efficiency and indoor-air-quality (IAQ) goals. Currently, many new-home blueprints and specifications don’t even identify the air barrier as a building component.

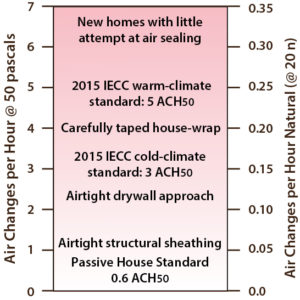

To meet California’s zero-net-energy (ZNE) requirements, builders must minimize air leakage. ZNE standards require air-leakage reductions of at least of half – from roughly 4 ACH50 in current production homes to 2 ACH50 or less. This air-leakage reduction represents about 15% energy savings compared to conventional new homes. Air-leakage studies estimate about 1,000 kilowatt-hours/year energy savings in a ZNE home, compared to conventional.

However air tightening faces the perceived barrier of indoor air pollution. The results of the SVACH project will reduce that barrier and thus improve both energy efficiency and IAQ.

Air-Leakage Principles

Air leakage is unintentional air exchange caused by air leaks and air-pressure differences between indoors and outdoors. The pressure differences originate from temperature differences, wind, and forced-air HVAC systems. The pressure differences drive air through the air leaks, which are flaws in the home’s building envelope.

Air leakage requires both an air leak and a pressure difference. The air-leakage rate depends on the surface area of leaks and pressure difference affecting them.

Air leakage can be a potent source of indoor air pollution, particularly from the ground, from building cavities, and from attached garages. However in some cases, the building envelope can filter outdoor air entering the home, which benefits reduces particle pollution.

Airtightness and Ventilation

Airtightness and ventilation work together to provide energy efficiency and healthy air.

Air leakage often carries pollution from the ground, the outdoors, or from intermediate zones like crawl spaces, attics, and attached garages. An effective air barrier between these areas and the living space excludes these pollutants from living areas. Airtight homes provide better indoor air quality because an effective air barrier blocks dust, pollen, smoke and other outdoor pollutants.

In tight buildings, the ventilation system and not unintentional air leakage, provides virtually all of the building’s fresh air. The more airtight the building envelope and the HVAC ducts, the more precisely the ventilation system can provide the correct amount of fresh air. The ventilation air exchange with outdoors removes moisture, carbon dioxide, and pollutants generated indoors. However, this outdoor air brings in particulates.

Airtightness and Particulate Pollution

PM2.5 means particles less than 2.5 microns in diameter. These small airborne particles are among the most hazardous pollutants found in homes. They are causes of asthma. lung cancer, allergies, bronchitis, and other respiratory problems. Most of a home’s smallest and most hazardous airborne particles come from outdoors.

Airtight new homes reduce these so-called PM2.5 particles compared to conventional new homes and existing homes. For example, leaky homes have small-particle concentrations of 45% to 60% of outdoor concentrations. Why are particle concentrations less indoors compared to outdoors? Because the building envelope acts as a filter, trapping some of the infiltrating particles. Airtight homes reduce the particulate concentrations by around 70% because their building envelopes are better filters than the envelopes of conventional homes. A very effective HVAC air filter (MERV 13-16) in an airtight home may reduce the particulate concentration more than 90% compared to outdoors.

Air Barriers

Building scientists created the air-barrier standards using a blower door. The blower door creates a large pressure difference across the materials, assemblies, and systems, in order to measure a home’s airtightness.

Builders construct air barriers around the heated envelope to minimize air leakage. The building industry has numeric standards for what kind of material, assembly, or building system constitutes an acceptable air barrier.

To build an air barrier, the builder begins with air-barrier materials like plywood, oriented-strand board, and drywall. These materials are verified air barriers. The builder seals the joints, penetrations, and boundaries between the air-barriers. An assembly, like a wall sealed at joints and penetrations creates an air-barrier assembly. When builders seal the joints between the air-barrier assemblies in an airtight manner, they create an air barrier system for the building.

Benefits of Superior Airtightness

- Greatly reduced small-particle infiltration compared to conventional buildings

- Ventilation works more effectively in airtight buildings than in leaky buildings

- Airtight buildings save energy compared to conventional buildings because controlled ventilation exchanges less air with the outdoors than uncontrolled air leakage

- Airtight buildings are much more comfortable than conventional buildings

- With a balanced ventilator, ventilation air comes from a filtered and clean source of outdoor air

Airtightness Benefits for California

Reducing natural infiltration in existing buildings is a high-benefit State goal. This goal requires contractors to install smart ventilation systems in new ZNE homes. The CEC-funded RESAVE study estimated that tightening California homes and providing adequate ventilation could save approximately $1 billion in annual energy costs.

The health costs of air-tightness without adequate ventilation are harder to estimate. We assume that health care costs would be substantially higher than the energy savings. More healthcare expenses are a barrier to air-tightening if we don’t optimize IAQ with smart ventilation. Health considerations could severely limit the CEC’s ability to promote ZNE homes.

The SVACH project results facilitates both acceptable IAQ, energy savings, and reduced peak-power demand.

Further Reading

Durable Airtightness in Single-Family Dwellings: Field Measurements and Analysis., 2015

Indoor Air Quality and Ventilation in Residential Deep Energy Retrofits., 2014.